The solid construction includes a welded frame and extremely robust lower and upper beam for clamping the sheets. Thanks to the narrowest bending beam on the market, the F series guarantees precise and flexible sheet metal profile production, even with very small stop dimensions.

The CIDAN F series is characterised by speed, power, easy to use and reliability. Its robust design includes a welded frame and extremely strong lower and upper beams for clamping your sheets. The double-driven folding beam is impressively stable, but at the same time so narrow that you don't have to step back during the bending process.

The machine is generously dimensioned, with an opening width of 150 mm and large recesses in the upper beam that allow even greater flexibility (49 mm high and 57 mm deep). The recess on the bending rail provides additional space for details on the bent profile.

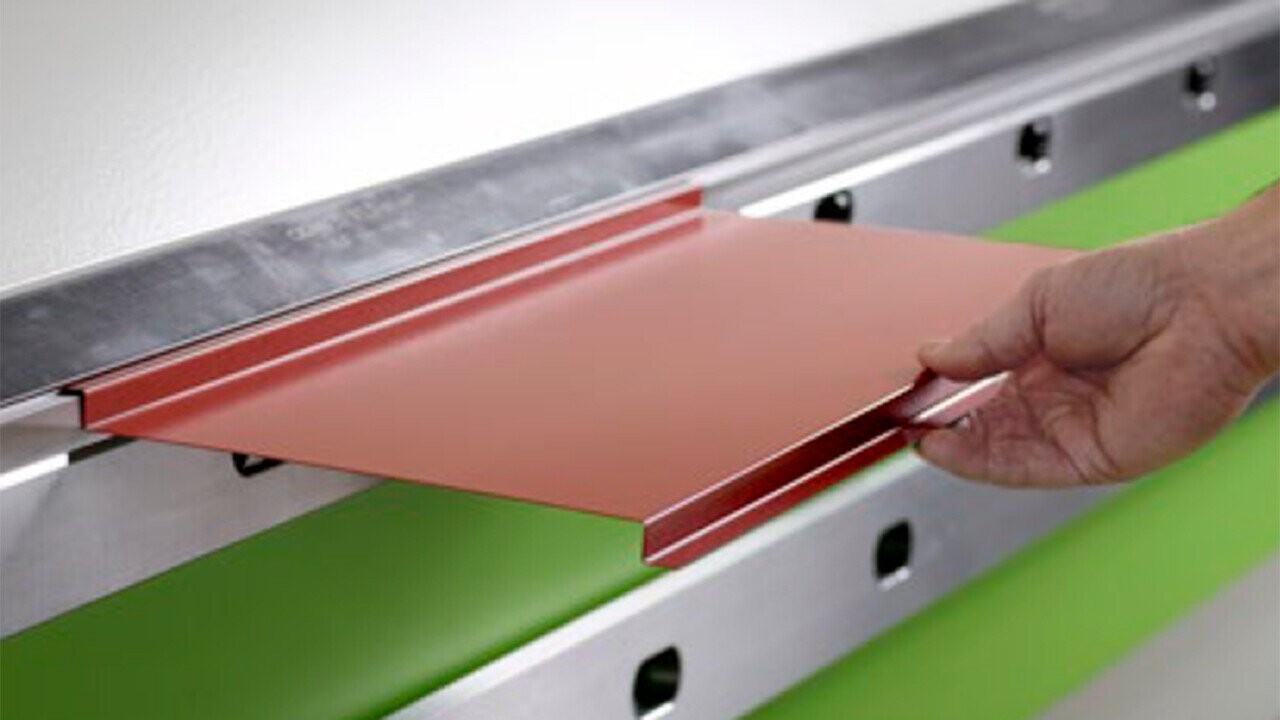

Supported by spring steel clamping fingers and the narrowest bending beam on the market, the CIDAN F ensures precision and exact processing. This ensures a high degree of flexibility even with very small stop dimensions. The bending beam can be changed quickly and easily in just a few simple steps.

The key benefits:

- Fast, user-friendly, and reliable.

- Adjustable crowning for perfect folding results for any thickness and width.

- Two folding rails as standard, with 7/10 mm and 15 mm widths.

- 8-16 gauging fingers depending on model and length required.

- Choose between two control systems: EasyLink or nuLink.