With the test set for dry substrates, users can quickly and effectively test non-conductive surfaces (e.g. PVC, TPO, bitumen, etc.) for pinholes, porosity, leaking seams and other leaks.

HERZ, a specialist supplier of roof welding equipment for laying roofing membranes on flat roofs, has added the PD240 Pro 2 dry leak detector to its extensive range of models.

As the importer for Germany, both the quality-oriented roofing company and the inspection-oriented expert will find this new dry leak detector to be a test method that considerably simplifies leak detection. In addition to the traditionally used wet leak detection method - which is time-consuming and involves additional work - the simpler dry leak detection method represents the inspection system of the future.

The Dry Pro system will offer reliable quality control, especially for roofing companies that value perfect craftsmanship and the best results with craftsmanship standards, even when using subcontractors.

Clear in design and function, easy to use, the dry testing method makes the roofing company stand out to planners, architects and building owners.

For decades, the English manufacturer Buckleys has been offering a tried and tested test method based on a current conduction method to detect leaks in tank construction. Based on this extremely strict quality control in tank construction, the principle was transferred to leak detection on dry flat roofs. In principle, the system uses the conductivity of the substrate (condensation/moisture on the underside of the roof is practically always present) under the membrane to create an "open circuit".

Its earthing together with the building structure and the building connection of the detector unit (copper wire brush) as well as the connection to the positive pole of the detector create the electrical test circuit. If the user passes the detector over a defective point in the membrane, the electrical circuit closes, as the membrane has a lower dielectric strength for the current at this point (the insulating property of the roof membrane is reduced or no longer present).

When the circuit is created, the current practically "jumps" through the gap to earth, triggering the alarm on the detector and alerting the user to a faulty point.

Complete testing system, easy to use

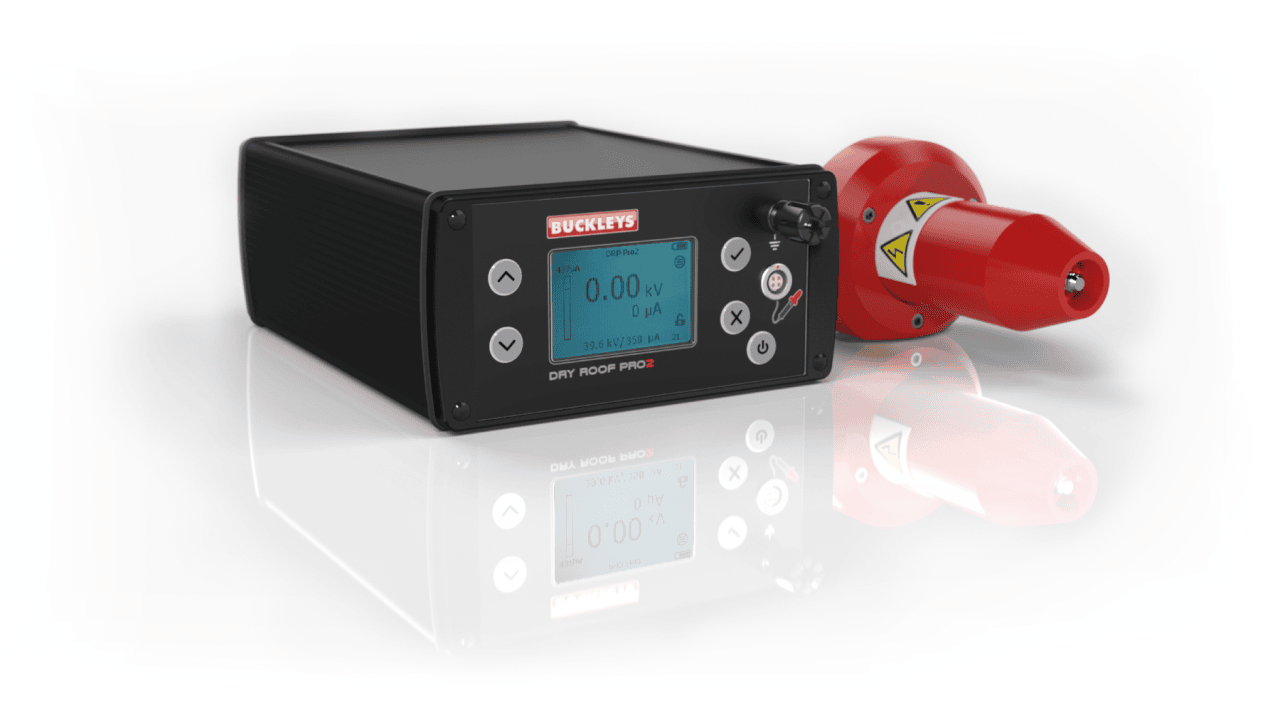

The battery-operated flat roof leak tester for dry weather conditions holds the complete test system in a handy system case. The compact control and display unit, which comes in a practical carrying case for hanging around, and the manually operated detector unit (copper brush) are immediately obvious. According to the importer, equipped in this way - and with the circuit closed via cable - up to 2,000 m² per day. This allows the exact location of leaks and faults to be determined, even if they cannot be seen with the naked eye.

The comprehensive test set also contains a whole range of useful accessories, including additional electrodes, which are used especially for corners and angles. In this way, even the smallest defects can be found, whether seams that have not been properly executed, leaking connections, cuts or even capillaries that are practically drawing water out of sight. With the PD240 Pro 2 dry leak detector, HERZ once again proves itself to be an innovative provider of flat roof solutions and complements its range of roof welding equipment to the benefit of the roofer.