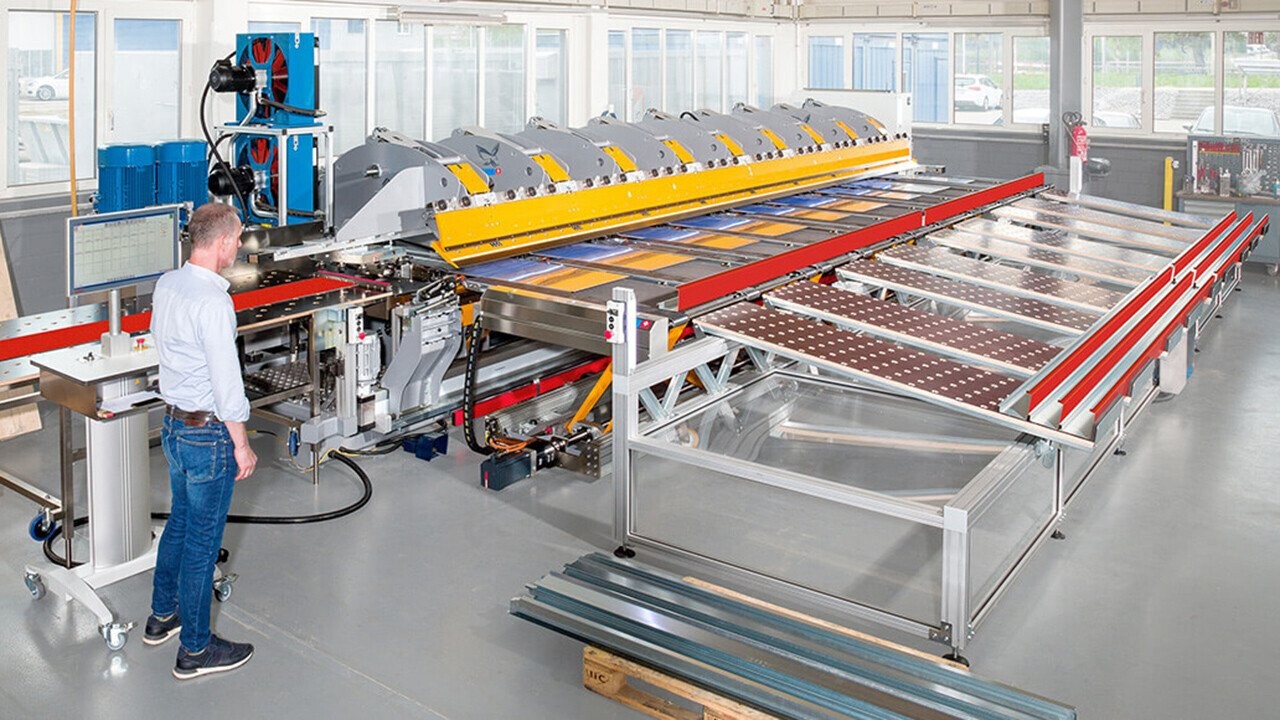

Based on THALMANN's unique kinetic control shaft technology, the TD DOPPELBIEGER ensures synchronous force distribution along the entire machine length. Modularly integrable automation units significantly and sustainably increase manufacturing efficiency.

The newly developed TD series from THALMANN stands for innovative swivel folding technology – such as control shaft technology, which is unique in the industry – and for profitable functions. It has been specially tailored to the needs of industrial and bending companies and offers our global customers many advantages.

With this model series, sheet metal working companies not only benefit from a powerful, efficient and highly precise swivel folding machine, but they also achieve clear competitive advantages over competitors:

QUALITY: We place great emphasis on meeting the highest quality standards. The TD series is manufactured exclusively with high-quality materials and meticulous workmanship to ensure reliable, long-lasting and consistent performance.

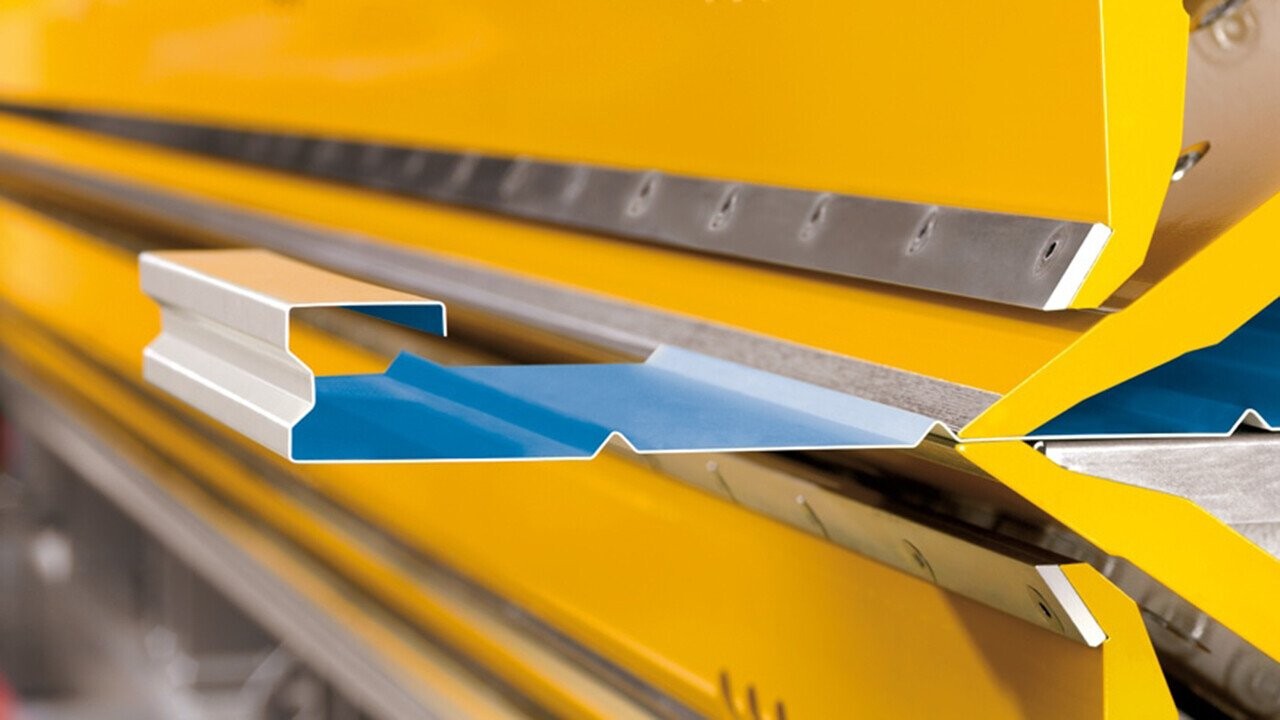

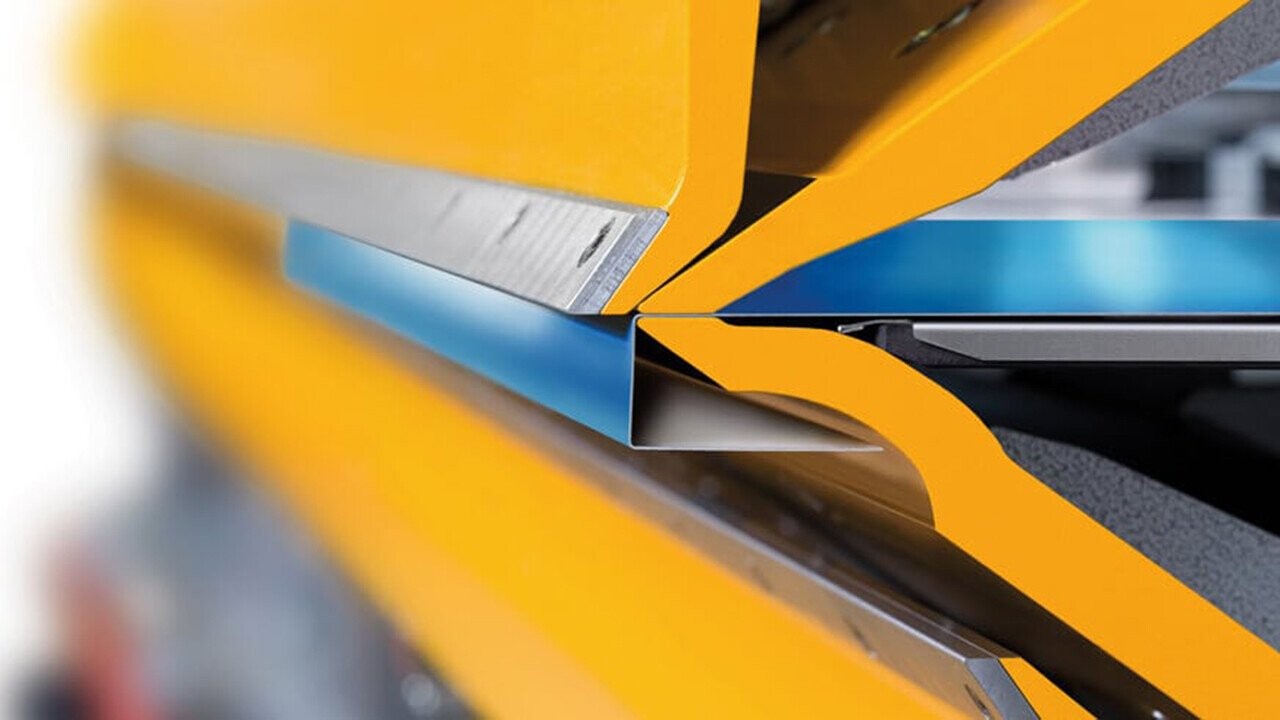

EFFICIENCY: The TD series has been developed to optimise production processes and to sustainably increase efficiency. With exclusive features such as Dynamic Folding Technology (DFT), precision is increased, speed is improved and valuable time is saved.

PERFORMANCE: The TD double folder from Thalmann offers impressive performance and enables sheet metal processing with high precision at amazing speed. Complex folding processes are completed efficiently and qualitatively impeccable results are achieved.

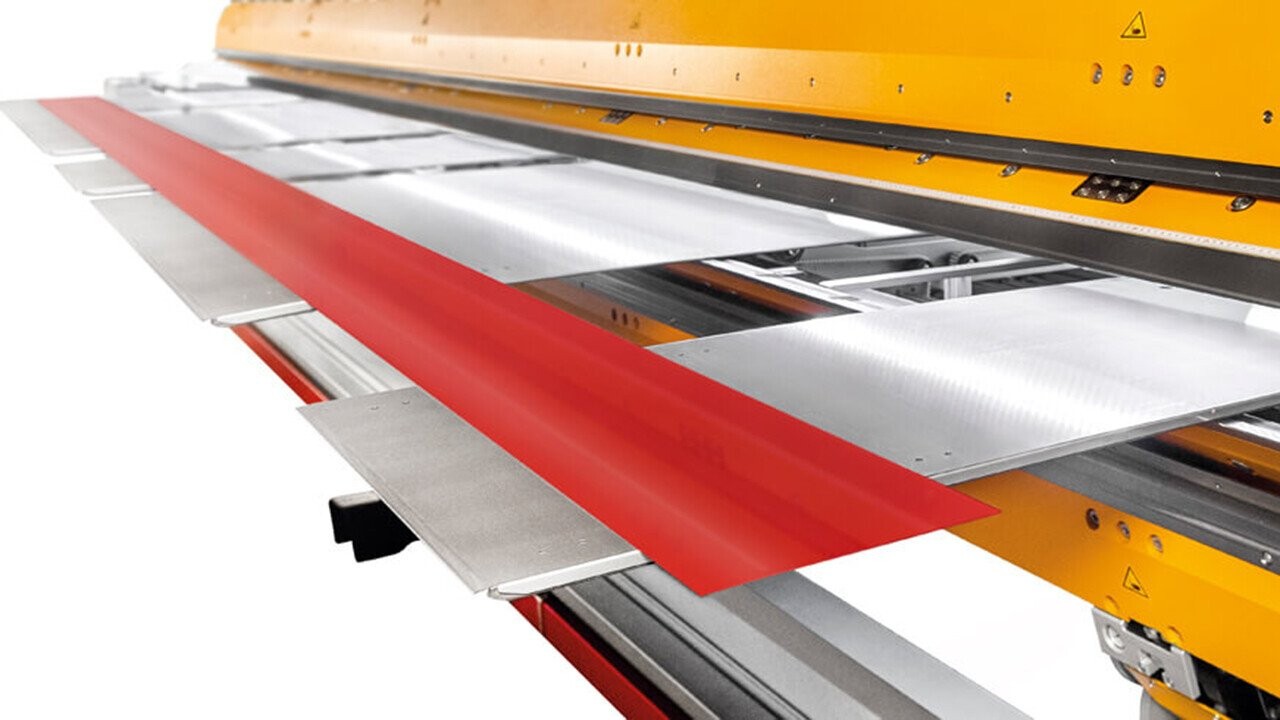

FLEXIBILITY: Flexible application possibilities play a co-decisive role for sheet metal working companies. The TD series enables variable machining of different materials, thicknesses and profile geometries – such as the smallest Z-foldings of only 13x13 mm.

SAFETY: The safety of the machine operators and their working environment is a top priority. The TD Series is equipped with sophisticated safety features and interlocks to ensure safe operation.

AUTOMATION: Three automation units that can be integrated in a modular way are optionally available for the TD series: automatic lateral sheet metal feed unit, an automatic sheet flipping unit and an automatic sheet metal unloading unit with folded parts buffer.

SERVICE: We offer our customers first-class, worldwide service and support from highly trained specialists. The service also includes a comprehensive spare parts guarantee.

Standard equipment:

- Kinetic control shaft technology

- Dynamic Folding Technology (DFT)

- Automatic material thickness adjustment

- Integrated crowning function

- Fully automatic gripper system

- Fully automatic depth stop

- Multi section grippers

- High-speed hydraulic drive

- Graphical CNC control with multi-touch widescreen monitor

- Complete safety equipment and interlocking

Options:

- Curved clamping beam tool

- Fully automatic, extendable handling table

- Electric longitudinal cutter

- Super-high-speed hydraulic drive unit

- Conical gripper function

- Adaptive double gripper units

- Tools made of Hardox 400 steel

- M-Guard remote maintenance module

- LED illumination of the folding line

- Automatic lateral sheet metal feed unit

- Automatic sheet metal flipping unit

- Automatic sheet metal unloading unit with folded parts buffer

Further Information:

Double folder

Double folder/automation