The guillotine shear RAPIDO has a robust construction and will cut all

thicknesses in the working interval without blade gap adjustment. The standard version is already well equipped.

The RAPIDO is a powerful guillotine shear that easily cuts sheets of different thicknesses in a single operation without the need to adjust the cutting gap. With working widths of 1,350 mm, 2,600 mm, 3,200 mm and 4,100 mm, it offers a wide range of options.

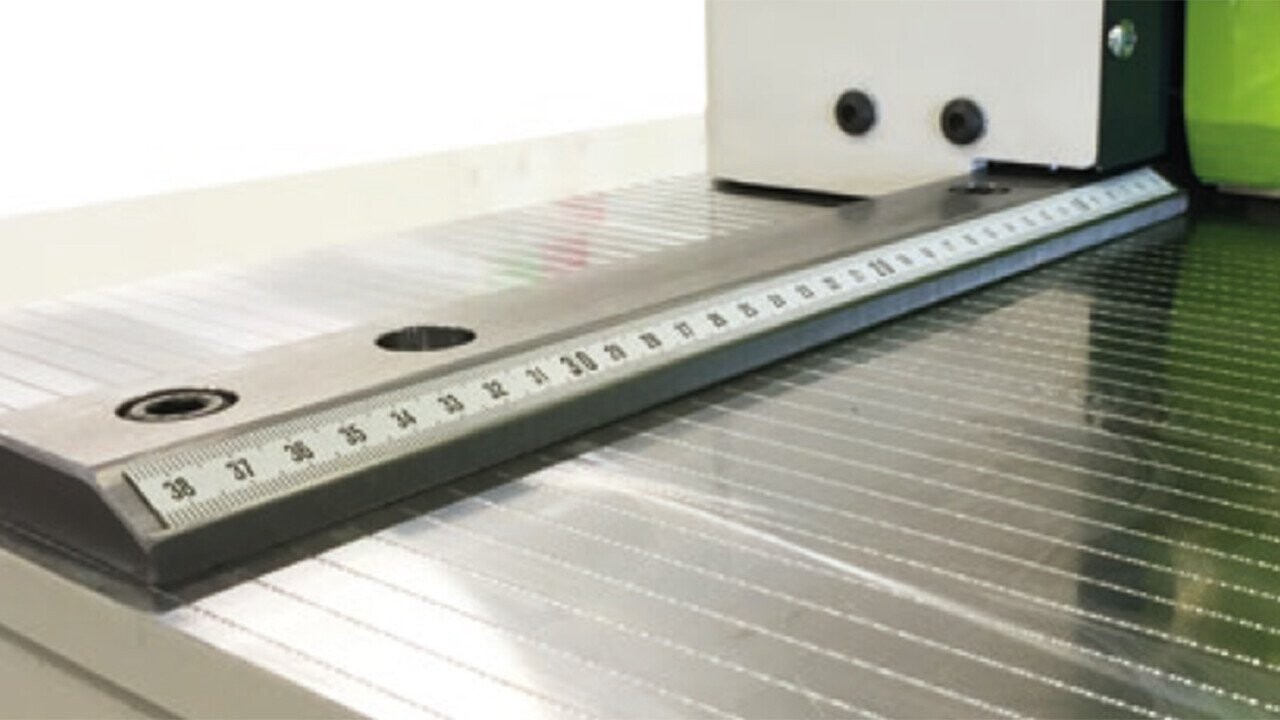

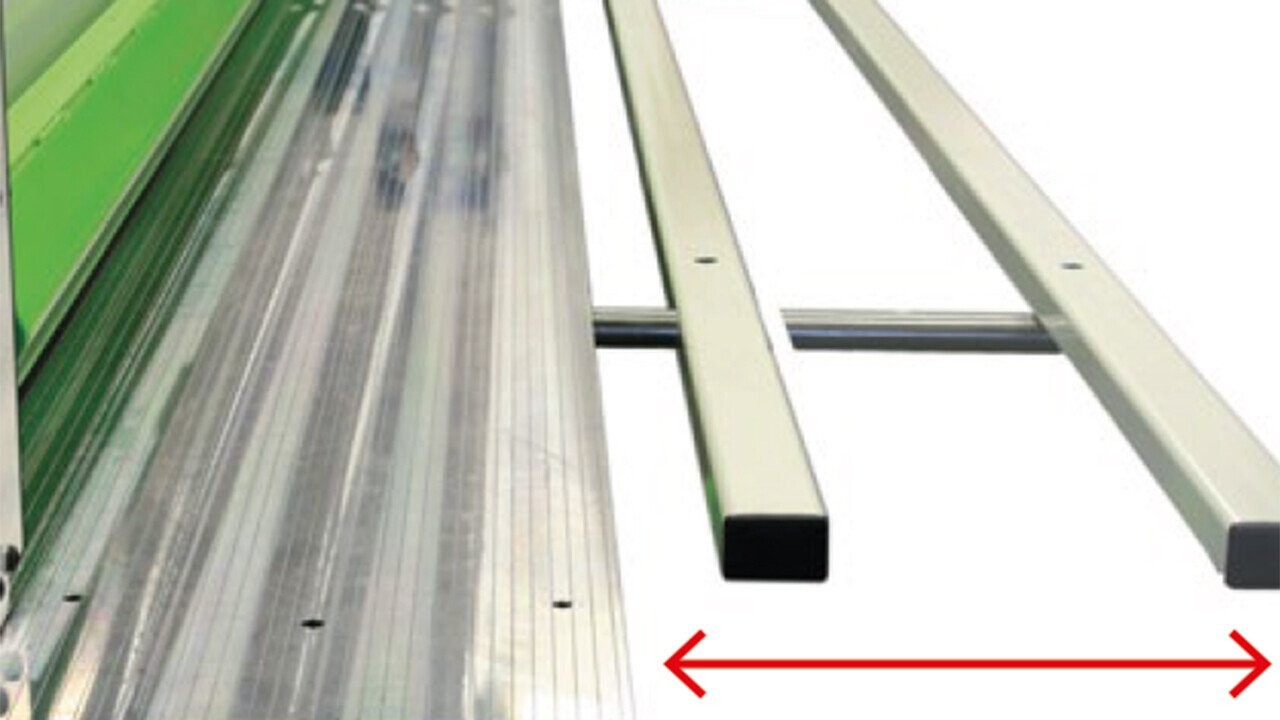

The machine is fully equipped from the standard model, and different back gauge lengths and sheet handling systems are easily added for smooth material handling. Working with a RAPIDO is a pure joy. The table with scored measuring lines at 10 mm spacing and squaring arm on both sides make it easy to move sheets, and you will always get accurate angles. With telescopic table extension you have excellent support for sheets over 1.5 metres (59”) in width.

The elegant design of the hold down beam means you can make maximum use of the sheets and the LED lighting above the cutting line makes it easy to cut exactly as scored. Gauge dimensions, quantity and all machine operations are easily set from the CutLink-control panel. No unnecessary commands, a minimum of keystrokes and the machine will do precisely what you want. The back gauge is designed for exact measurements and smooth movements.

The back gauge motor is placed directly on the stop arm for low noise output and leaves a free area on the upper side of the machine. RAPIDO maintains an impressive speed at 35 strokes per minute. The electric gear motor is very powerful and consumes energy only on each stroke.

This shear’s built-in ergonomics and low noise output provide a good and comfortable working environment. In addition, the machine is designed so that periodic maintenance and all service points are reached without hassle.

Key benefits summarized:

- Powerful! Wide working range without the need for blade gap adjustment.

- Fast! 35 strokes per minute.

- User-friendly and easy to operate.

- Comes well-equipped as standard.

- Slender hold-down beam minimizes waste.

- Scored measuring lines on the table for precision.

Examples of optional features:

- Telescopic table extensions.

- Pneumatic hold-down beam.

- Squaring arm with or without T-groove and tilting stops.

- Moveable wagon for enhanced mobility.